THE “VIRTUOUS” CIRCLE OF BENCORE MATERIALS

Recollection, Recycle and Reuse: the three Rs that make Bencore’s approach to the production of panels for architecture and design a clear path towards sustainability

Reduce the environmental impact to a minimum, have control over the entire life cycle of materials both in interior architecture and design: these topics have now become almost imperative and there is no doubt that both bioarchitecture and ecodesign have long been focused on those materials and their applications that fall within this specific category. Companies now invest and innovate on those technologies that are able to bring them closer to the horizon of ‘sustainability’.

The advanced technologies of Bencore composite panels absolutely go hand-in-hand with the concepts of circular economy and sustainability. This particular sensitivity has always belonged to Bencore which is a member of Green Building Council in Italy, a professional community operating in the field of sustainable construction that promotes and supports the transition of the market towards sustainability through the promotion of a third-party certification system and certification protocols (GBC systems) specifically developed for the peculiarities of the Italian market, whose parameters set precise criteria for the design and construction of healthy, energy-efficient buildings with low or low environmental impact.

The Three Rs of Bencore describe in detail this “green” path, made of awareness and constant attention: Recollection, Recycle and Reuse. For some Bencore products, recycled raw materials are used at the end of the first phase of the life cycle and, in combination with the durability and strength of the material, they greatly lengthen the life cycle of the product itself. Where it is not possible to use recycled leftovers, high-quality raw materials are used to guarantee the finished product a life much longer than the average of similar products and materials thanks to their intrinsic characteristics.

In addition to this, with their lightness, Bencore panels have lower transport and application costs than the average and, with their transparency, they facilitate the passage of natural light between spaces with considerable energy savings. Finally, the production waste is enhanced by making samples of the materials to be sent to professionals or for the creation of works of art that, like those of Paolo Nicolai, give a second and noble life even to the smallest of the wastes.

The main sustainable materials produced by Bencore

Ecoben Wave Green Cast

This material consists of a core in recycled cardboard and 100% recycled and recyclable acrylic skins. In this case the regeneration technology allows to obtain from leftovers a whole new raw material of the same high quality as the starting ones. The panel is suitable to be worked in different ways including inclined cuts for the realization of corner joints between the panels, special and curved cuts, shiny, satin, colored or transparent edges.

Wasbottle

This material is born in 3 main variants (one in 100% recycled and recyclable HDPE and the other two in 100% recycled and recyclable PETG) ideal for producing complements such as table tops, shelves, partitions for interior design and architecture. The Wasbottle project is born from the recycling of dismissed plastic for everyday use and it was developed in collaboration with Autogrill, the first operator in the world in catering services for travelers.

Smile Plastics: panels made of 100% recycled and recyclable materials. Obtained by direct pressing procedures of plastic waste, each panel is in fact unique and different from each other. Bencore acts as Smile Plastics exclusive distributor for Italy.

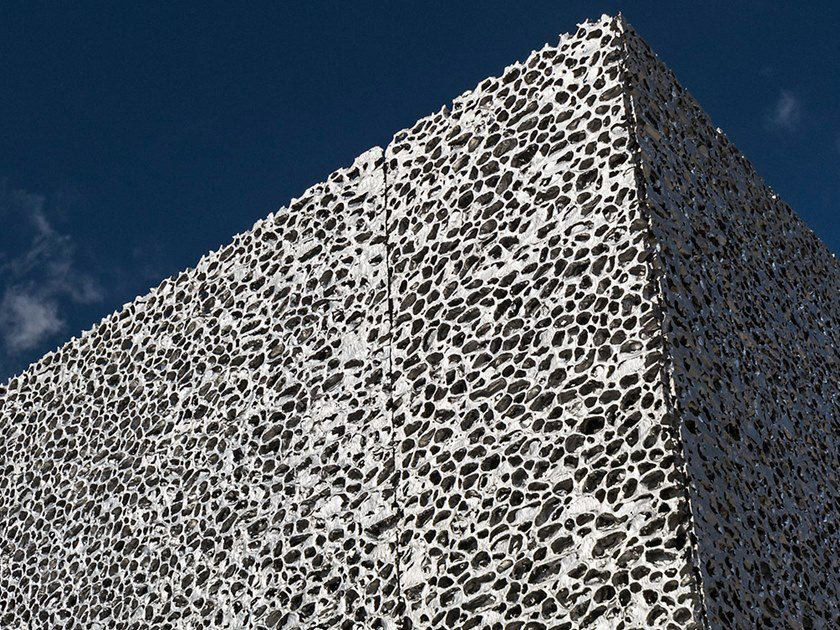

Alusion: stabilized aluminum foam. The characteristic appearance is achieved by injecting air into aluminum when it is in the melting state. Produced in continuous slabs, but also in special formats, it is 100% recyclable. Bencore acts as Cymat Technologies-Alusion exclusive distributor for Italy and other European countries.

Kaynemaile: is an architectural mesh in self-extinguishing polycarbonate through a continuous injection process that generates a three-dimensional structure, without joints or seams, which is very resistant to any type of impact. Bencore acts as Kaynemaile exclusive distributor for Italy.

Paolo Nicolai’s Art: when Bencore waste acquires value and becomes real Art

Already oriented with its Mission towards the recycling of wastes and a more sustainable production, today Bencore is joining Paolo Nicolai in his artistic path, an artist from Carrara who is dedicating his career to creativity and art: the artist’s goal consists in giving new life to dismessed plastics and other types of pollutants present in the environment, which are at the end of their life cycle or resulting from the waste of different productions/processes.

We are talking about PET, PVC, HDPE, PMMA, or Plexiglas, Polycarbonate, but also marine wastes, toys, medicines just to name a few: to these the wastes resulting from the production of Bencore honeycomb panels are also added with their different cores, colors and transparencies.

The results are magnificent sculptures, of classical inspiration, but with a clear pop, post-modern and highly contemporary message, that Paolo Nicolai is proposing to a very receptive audience which is perfectly able to appreciate the absolute value of these works.

In this way Bencore wastes themselves take on a new value: creating something whose life cycle is not destined to reuse but rather to create and disseminate a new form of art, eternal and lasting to give life to a post modern ideology in which plastic, with its millennial persistence, is ennobled to take on a whole new meaning.

Bencore Circular Economy interpreted by the Artist Paolo Nicolai, here’s the official video:

Bencore Circular Economy interpreted by the Artist Paolo Nicolai, here’s the official video:

https://youtu.be/gOl-bK_KQJo